The global manufacturing landscape is changing quickly, and Mexico has emerged as a critical destination for companies shifting their production operations. Multiple factors drive this trend, making Mexico an appealing option for businesses seeking to cut costs, tap into a large market, and optimize their supply chains. Mexico’s competitive labor costs are the most prominent factor behind this shift. Manufacturing wages in Mexico are significantly lower than those in developed nations like the U.S. and Canada, leading to substantial savings in production expenses, allowing companies to boost profit margins or offer more competitive pricing to consumers. Cost-effectiveness remains the most significant reason companies migrate and outsource to Mexico.

Improved Cost Efficacy

While the pandemic significantly impacted raw material suppliers across the United States, forcing many to shut down operations, U.S.-based manufacturers increasingly turned to international sources for their raw materials. The shift in supply chains brings with it several potential challenges. Manufacturers may need higher production costs domestically, along with possible delays in manufacturing and shipping, particularly if materials get held up in customs. For companies not secured by long-term contracts with American manufacturers, a rise in manufacturing costs is likely on the horizon, leading to difficult decisions around raising product prices—which might be challenging in today’s medically cautious climate.

To offset these rising costs, many businesses are considering nearshoring to Mexico as a strategic solution. Mexican manufacturers present several key advantages, including access to a skilled labor force at competitive wages, efficient and cost-effective shipping options, and a track record of reliability and expertise in production. While China and other overseas locations may also offer low-cost manufacturing alternatives, these options often come with additional hurdles, such as longer lead times and potential supply chain disruptions. By contrast, Mexico’s Proximity to the U.S. provides businesses with a more agile and resilient supply chain solution, making it an attractive choice for companies looking to stabilize and reduce their production expenses during these uncertain times.

Coastline International Improves Your Bottom Line

Mexico offers a compelling opportunity for manufacturers seeking to reduce costs, access a vast market, and streamline operations. With its skilled workforce, strategic location, and supportive government, Mexico remains a crucial player in the global manufacturing industry for years to come.

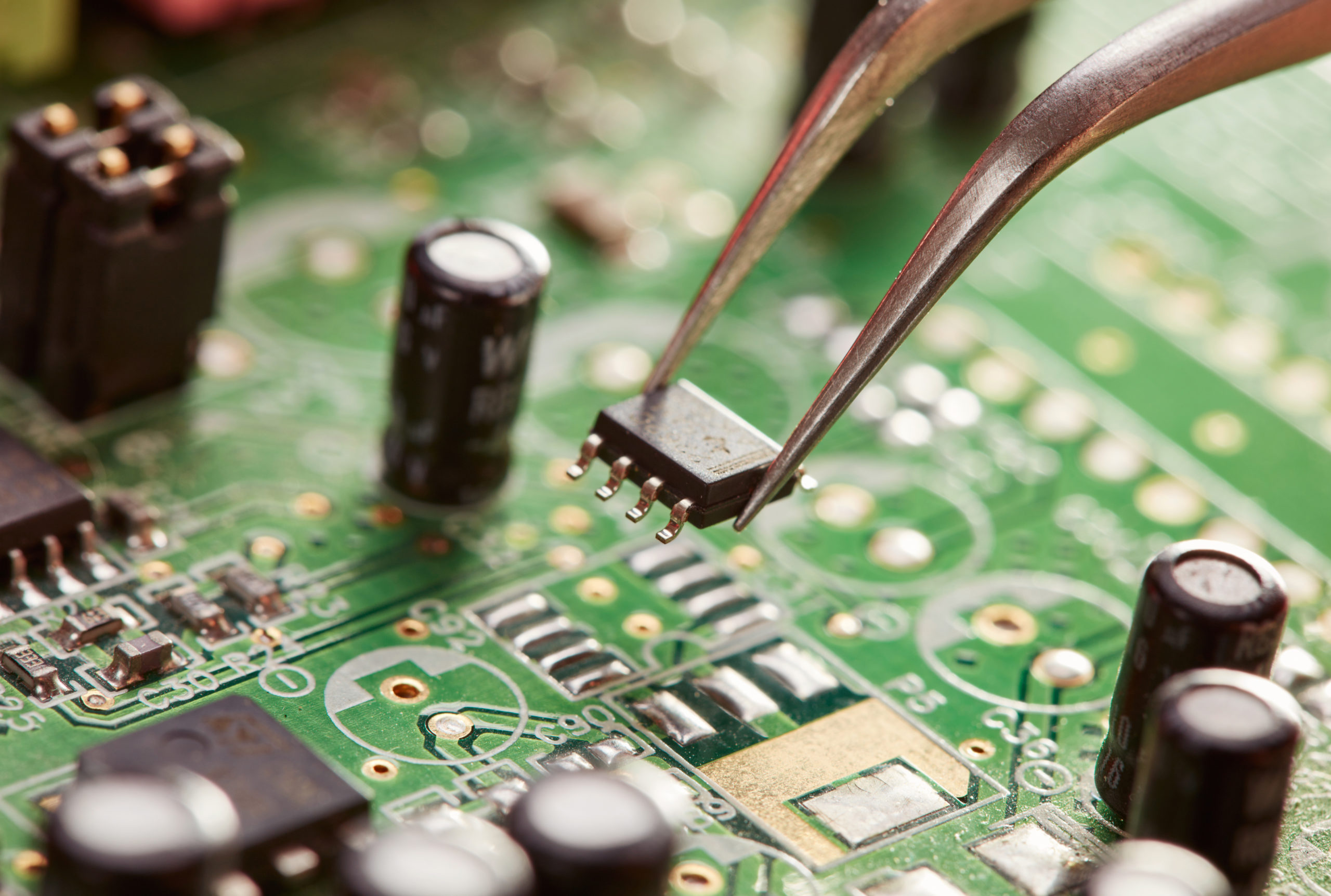

Coastline International has been a reliable manufacturing partner since 1982, serving various renowned organizations in the Medical, Electronics, Aerospace, and Consumer Goods sectors. Based in San Diego, California, Coastline is a privately owned U.S. corporation with manufacturing facilities in Tijuana, Mexico. Our typical clients develop and sell products in both U.S. and international markets. Over the past 40+ years, we have been the trusted partner of numerous large and small companies that outsource their manufacturing for strategic or economic reasons. Additionally, we offer shelter services to support client companies that choose to manage their production operations in Mexico.

Please fill out our contact form or call 888-748-7177 to see how we can help expand and improve your manufacturing pipeline today!