Medical Device Manufacturing

Quality manufacturing services you need provided

by the responsive partner you deserve

Medical Device Manufacturing in Mexico: 40+ Years of Excellence

Finished device assembly you can count on

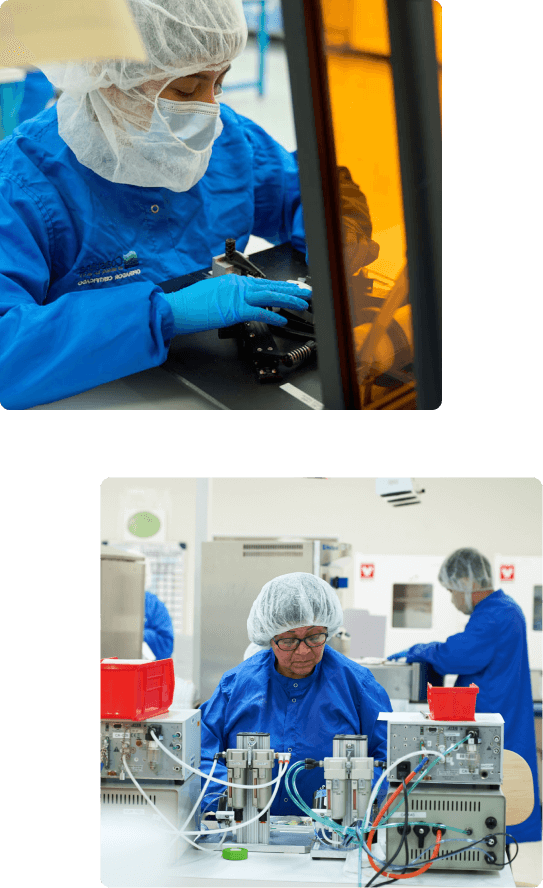

Coastline provides experienced, timely medical device manufacturing and precision assembly. We are fiercely committed to exceeding your expectations for product quality, delivery, and service, helping you consistently meet the evolving demands of your industry. All medical production is completed at Coastline’s FDA registered medical device manufacturing facilities to ISO 13485 standards (ISO 13485:2016).

Mexico’s medical device industry continues to grow through strategic partnerships with leading companies worldwide, and Coastline’s position within this dynamic ecosystem offers significant advantages.

Our access to established supplier networks that specialize in components for medical devices, close collaboration with research institutions, and strong integration with global supply chains allow us to more efficiently produce and distribute medical equipment.

Comprehensive Services

Coastline has manufactured products for medical device and life science OEM clients for four decades.

We know what it takes to meet the increasingly demanding quality standards associated with assembly and packaging in the medical device, biotech, life science, and pharmaceutical industries.

Consistent Quality at a Lower Cost

OEM clients typically find the cost of our medical device manufacturing services to be 30% or more below other contractors or the client’s own in-house costs.

Since Coastline is a nearshore manufacturer, OEM clients may also benefit from lower transportation costs and reduced transit time.

ISO Class 8 Clean Rooms

We operate several Class 8 (Class 100,000) clean rooms within our FDA registered medical device manufacturing facilities.

Of the total 65,000 square feet of manufacturing space, Coastline has expanded to over 12,000 square feet of cleanroom space. All medical production is completed in ISO 13485 standards (ISO 13485:2016).

- Capabilities

- Major Product Categories

- Quality & Regulatory

- Qualification Services

Capabilities of Medical Device

Manufacturing Operations

- Finished Device Assembly

- Manual Assembly of Components & Subassemblies

- Box-build & Mechanical Assembly

- Precision Assembly under Microscope

- Kitting of Specialty Procedure & Surgical Kits

- Cleanroom Assembly & Packaging

- Printing & labeling

- Serialization & Lot Traceability

- Materials Management: Procurement & Logistics

- Sterile-barrier Packaging

- Soldering (IPC standard)

- Battery Pack Assembly

- Solvent bonding

- UV Curing & EFD Adhesive Processes

- Ultrasonic Welding

- RF Welding (Radio Frequency)

- Friction-fit assembly

- Process Qualification & Validation Activities

- Automation & Semi-Automated Processes

- Adhesive Processes; Gluing and Bonding

- Textiles; Soft Goods Sewing

- Thermoforming

- Form-Fill-Seal (FFS) Packaging

- Sterilization (contract) & Sterilization Management

- Inspection Services

- Metrology: Optical Measurement System (OMM)

- Lean Manufacturing Principles

- Program Management

Major Product Categories for Medical

Device Manufacturing in Mexico

Some examples include:

- Class I, II, III Devices

- Infusion therapy

- Blood Collection / Blood Management

- Surgical Technologies

- Orthopedics

- Aesthetics

- Ophthalmic Devices / Ophthalmology

- Bariatrics

- Diagnostics

- Drug Delivery

- Single-use Devices

- Implantables

- In Vitro (IVD)

- Life Sciences

- Biotechnology

- Pharmaceutical

- Disposables & Consumables

- Medical Equipment & Supplies

- Phlebotomy

Examples of Medical Devices Include:

- Specialty Surgical Devices

- Tubing Sets

- IV Administration & Extension Sets

- Enteral Feeding Sets

- Wound treatment (including vacuum drains)

- Specialty Suture Devices

- Blood Collection Devices

- Needle sets

- Catheter Assemblies

- Custom Procedure & Surgical Kits

- Ophthalmic Devices

- Custom Medical Liners, Pads, Straps

- Surgical Staplers

- Laparoscopic Surgical Devices

- Diagnostic test Kits

- Specimen Collection Devices

- Specialty Products for Medical & Aesthetics Industries

Quality & Regulatory Compliance

At Coastline, regulatory compliance is paramount to our Mexico’s medical device manufacturing operations. Our facilities and processes are designed to meet and exceed international standards for medical devices.

Comprehensive Regulatory Framework:

- FDA-registered facilities with full compliance monitoring for medical devices

- ISO 13485:2016 certified quality management systems

- Adherence to Good Manufacturing Practices (GMP) for medical and pharmaceutical sectors

- Regular internal and third-party audits

- Intellectual property protection for all client designs and processes

Quality Assurance Throughout the Process:

- Incoming materials inspection and verification

- In-process quality checks at critical control points

- Final medical products inspection and testing

- Comprehensive batch record documentation

- Continuous improvement initiatives promoting health technology excellence

Qualification Services for Manufacturing

Medical Devices

- Full transfer of production lines

- Program Management

- Quality assurance testing

- Metrology

- Optical Measurement Systems (OMM)

- First article inspection

- Production qualifications

- Process qualifications

- Fixture qualifications

- Equipment repair & maintenance

- Process validation

- Sterilization management

- PFMEA

- IQ – OQ – PQ

- Full-service incoming inspection

Medical Device Procurement:

Logistics & Import-

Export Services

Coastline minimizes customer investment of time and resources by handling all logistics for transporting or importing all raw materials and components for medical devices to its manufacturing facility in Tijuana, Mexico. This includes:

- Materials management and warehousing

- Tracking and lot traceability

- End-to-end turnkey solutions as needed

- Procurement: components & supplier sourcing

- Mexico-USA importation/exportation services

- Customs processing management, with ability to release goods landed in the US

- Import-export expertise for OEMs to ship finished medical devices to the US and globally

- In-bond shipment capabilities and utilization of free-trade agreements

- IMMEX certified

Advantages of Mexico as a Medical Device Manufacturing Hub

Mexico’s medical device industry has grown significantly in recent years, making it a premier destination for medical device companies seeking to optimize their production processes.

The strategic location, skilled workforce, and favorable business environment have established Mexico’s medical device manufacturing as an ideal choice for companies in the medical device market, since it enables:

- Same-day or next-day delivery of medical devices to major US markets

- Reduced shipping costs compared to other international manufacturing industry locations

- Similar time zones facilitating real-time communication for medical device production

- Easier site visits and quality inspections of medical devices by US-based management

- Faster response to medical device market demands and supply chain disruptions

- Experience with precision assembly of medical devices and quality control processes

- Lower labor costs than the US while maintaining high-quality medical devices

- Strong work ethic and dedication to precision in the medical device manufacturing industry

- Coastline’s corporate location in San Diego allows for executive leadership to be on-site in Mexico daily

Explore a Medical Device

Manufacturing Partnership

Get in touch to learn more about how Coastline International can you

help you with top-quality, on-time manufacturing and packaging

Looking for Additional Information?

Frequently Asked Questions for the Medical Device Manufacturing Industry

Frequently Asked Questions for the Medical Device Manufacturing Industry

Contract manufacturing in the medical device industry is very common, in which OEMs (original equipment manufacturers) work with contract manufacturing organizations, often referred to as CMOs or third-party manufacturers, to manufacture their product. The contract manufacturers are required to manufacture the product to the original specifications and meet all quality requirements, effectively having no difference than being produced by the original manufacturer.

There is a vast array of products used in the medical device industry (diagnostics, surgical, treatment, therapeutic, monitoring, aesthetics, and more) of which have immensely high usage volume. These products and devices require sufficient manufacturing resources to support the demand and as such medical contract manufacturing has become a viable solution to provide such scalable solution. This often includes international sites and strategic partners to provide support in design, manufacturing, and transportation/logistics to healthcare locations throughout the world.

What are the major steps in manufacturing medical devices?

The pathway from product concept to scalable manufacturing status can be quite daunting. While having a great idea for a medical solution is fantastic, it requires some major steps to get from idea to manufactured finished good. The major steps in manufacturing medical devices are:

- Initial concept

- Product design

- Prototyping

- Regulatory Requirements (if applicable)

- Device testing

- Design verification and validation

- Product manufacturing

- Sterilization (if applicable)

How is Coastline’s nearshore medical device manufacturing better than offshore?

Outsourcing your medical device manufacturing needs is a great step when it comes to increasing efficiency, reducing costs, and increasing overall production capacity. However, choosing where in the global medical device market to outsource plays a significant role in the outcome.

Nearshore medical device manufacturing in Mexico can offer you easy access to the facility, quick shipments of finished products, and a highly trained, quality manufacturing team, while also achieving the cost reduction and increased capacity to scale.

What are the benefits of using Coastline for my medical device manufacturing in Mexico?

Coastline International has been providing medical device manufacturing support to leading global OEMs for many years. Established in 1982, Coastline has been in the medical device manufacturing industry in Mexico for over 40 years and has developed a well-established team and facilities to provide manufacturing solutions across many applications.

We have all witnessed how strained the healthcare system in the U.S. can get during a crisis. If you have a medical device or a piece of medical equipment that needs to be manufactured, you need to have the confidence that it can be handled by an experienced, qualified facility with a thoroughly trained team. You want your finished product to arrive where it is needed when it is needed.

At Coastline, we meet your demands – without sacrificing quality – to provide you with finished products that meet all necessary standards. The entire process saves your company both time and resources.